PRODUCTS CENTER

Product Description

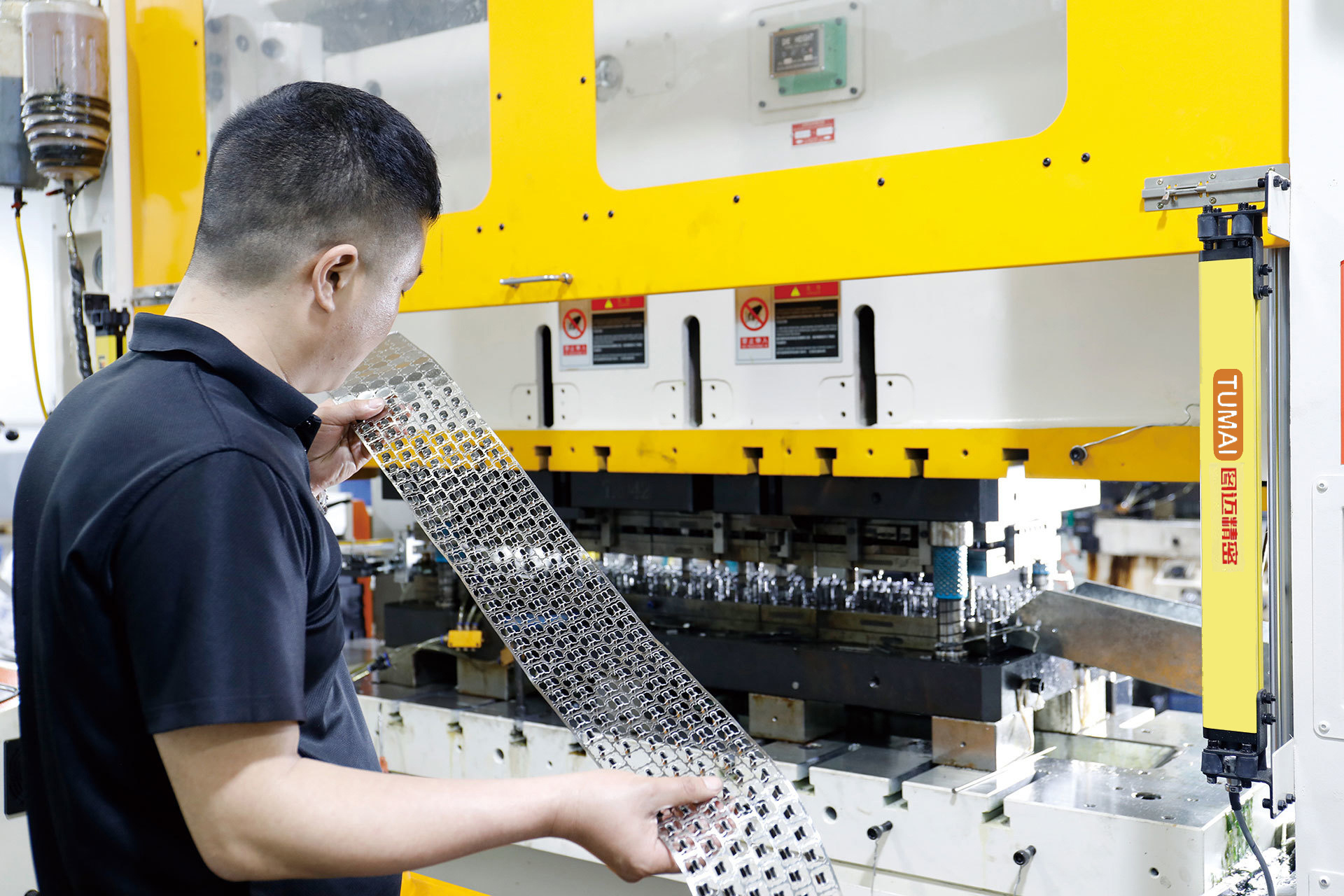

Stretch extension stamping parts are specialized components crafted through the stretch stamping process, which involves shaping metal sheets by stretching and forming them into desired configurations. This manufacturing method allows for the production of parts with complex geometries, including deep cavities, curved surfaces, and elongated shapes, making them ideal for applications in automotive, aerospace, and household appliances.

One of the key advantages of stretch extension stamping parts is their high material utilization. The process minimizes material waste by precisely shaping the metal sheet, ensuring that most of the raw material is incorporated into the final product. This efficiency not only reduces production costs but also aligns with sustainable manufacturing practices, which are increasingly important in modern industries.

Strength and structural integrity are notable features of these stamping parts. The stretching process work-hardens the metal, enhancing its tensile strength and resistance to deformation. This makes stretch extension stamping parts capable of withstanding heavy loads and harsh operating conditions, such as those encountered in automotive chassis components and aerospace structural parts. Their robust nature ensures long-term performance and reliability in demanding environments.

Versatility is another significant benefit. Stretch extension stamping parts can be made from a variety of metals, including steel, aluminum, and copper alloys, each chosen based on the specific requirements of the application. For example, aluminum parts are lightweight, making them suitable for aerospace applications, while steel parts offer high strength for automotive use. This adaptability in material selection, combined with the ability to produce complex shapes, makes these stamping parts highly versatile across different industries.

: next page