Customized Stamping Parts and Mold Services

We are committed to providing customers with high-quality customized stamping parts and mold solutions. The company is equipped with a variety of high-performance equipment, including Xingli open single-point high-performance punch presses, Zhenli punch presses, C-type precision punch presses and other precision punch presses, as well as fiber laser marking machines, fine hole discharge machines and precision surface forming grinders to ensure the efficiency and accuracy of products during processing.

To meet various complex needs, we have also introduced Wanhao image measuring instruments and Zhonggu Nikon projectors for dimensional inspection to accurately control product tolerances. At the same time, Qunji spark machines and grinder equipment support the precision manufacturing and repair of customized molds.

Whether it is small-scale production or large-scale customization, we can provide one-stop service, from design, proofing to production, using advanced technology and equipment throughout the process to ensure that every product meets your expectations. Contact us to turn your product from concept to reality!

1

Custom mold design

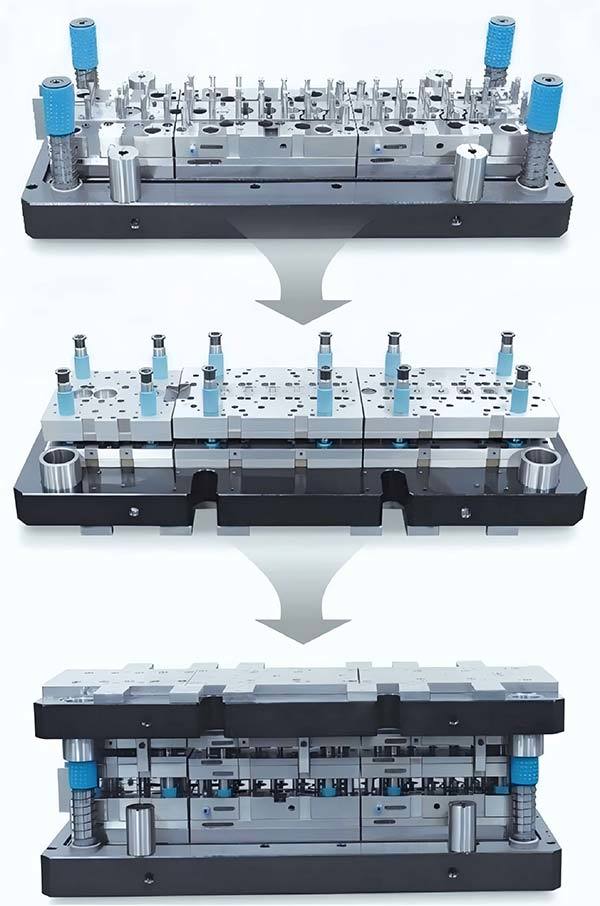

- Mold design is the starting point of the manufacturing process and directly affects subsequent production efficiency and product quality.

- Demand analysis and solution formulation: Combine customer needs, deeply analyze product structure, functional characteristics and application environment, and propose feasible solutions.

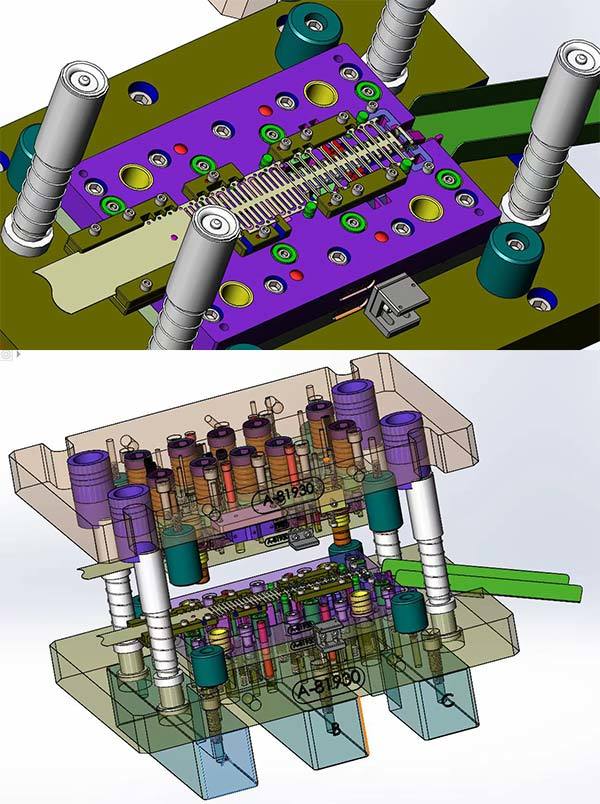

- Digital modeling and simulation: Use advanced CAD/CAM/CAE technology for 3D modeling and structural optimization, and use simulation tools such as mold flow analysis (Moldflow) to predict potential problems such as injection flow path, filling time, shrinkage or deformation.

- Material and process selection: Select suitable mold steel (such as P20, H13 or beryllium copper alloy) according to production needs, and determine the surface treatment process (such as nitriding, chrome plating or polishing) to improve the durability and precision of the mold.

- Modular and refined design: The modular design concept is adopted to facilitate mold maintenance and component replacement, and the design details are optimized (such as guide pins, guide sleeves and cooling systems) to improve the stability and service life of the mold.

2

Parts production

- Mold parts production is a key link from design to physical transformation, requiring high-precision and high-efficiency manufacturing processes.

- High-precision processing equipment: Use high-precision CNC machine tools (CNC), electrical discharge machining (EDM), wire cutting machines and laser cutting equipment to process parts to ensure that dimensional tolerances and shape tolerances meet design requirements.

- Multi-process coordination and integration: Implement multi-process processing such as turning, milling, drilling, and grinding, and use automated equipment to optimize the processing path to achieve dual guarantees of efficiency and precision.

- Surface treatment and durability improvement: Improve the strength and wear resistance of parts through heat treatment (such as quenching, tempering) and surface treatment (such as titanium plating, nitriding) to ensure that they can adapt to high-frequency working conditions.

- Inspection and assembly: After the parts are processed, they are fully inspected, including dimensional measurement, hardness testing and surface roughness testing to ensure that they meet the design standards. Professional tools and equipment are used during assembly to ensure precise matching between parts.

3

Customized support and service

- After the mold is delivered, we provide comprehensive technical support and services:

- Technical documents and training: Provide mold design drawings, instructions and maintenance manuals, and conduct on-site training for the customer's operation team.

- Regular maintenance and repair services: Develop a maintenance plan within the mold life cycle, replace wearing parts in time, and extend the life of the mold.

- Quick response and improvement: Provide quick response services for customer feedback, and optimize and upgrade the mold when necessary.

- Through the above professional management and technical measures, the rigor, accuracy and reliability of mold customization design, parts production and quality control processes can be ensured to the greatest extent, thereby meeting the high standards of customers.

Mold design and manufacturing is a key link in modern industrial production, covering the entire process from concept to finished product. Through mold design and mold customization, efficient and accurate mold solutions can be developed according to customer needs.

- In mold processing, advanced CNC mold processing technology ensures high precision and consistency of products, and is particularly suitable for the production of precision molds and non-standard molds. For small-scale production with less demand, small-batch mold production provides a cost-effective option. At the same time, mold optimization can further improve the performance and production efficiency of the mold.

- For complex projects, rapid prototyping molds can shorten the development cycle and provide strong support for production and manufacturing. From large-scale application of molds to targeted mold repair services, they all reflect the diversity and flexibility of technology and inject momentum into the development of various industries.

- Our metal stampings and precision stampings are unparalleled in quality and precision. With advanced stamping processing, stamping manufacturing, and stamping design capabilities, we are able to produce a variety of complex parts. At the same time, we have a very high technical level in stamping mold processing and can provide efficient and reliable solutions according to customer needs.

- We have more than 10 years of experience as tool and die maker and tool and die designer in the metal stamping industry. Whether it is product development or production manufacturing, we always create value for customers with excellent quality and innovative technology.